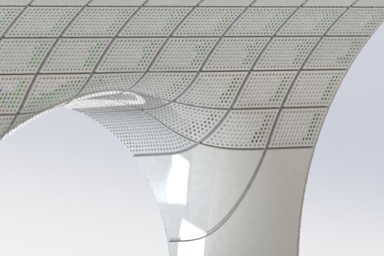

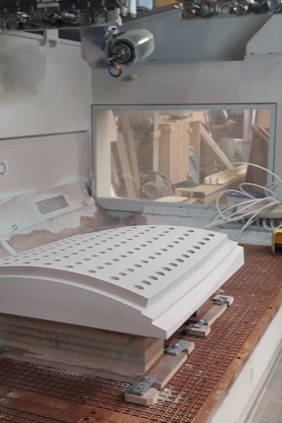

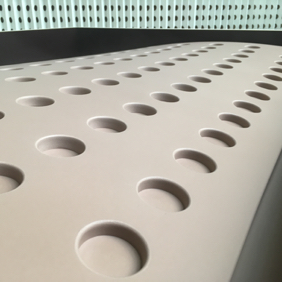

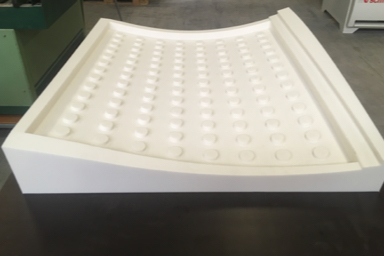

Highly-complex casting molds

A total of 86 basic types of panel in a wide variety of geometries were needed for the project’s facade. In order to produce the often highly-complex polyurethane casting molds for the facade elements, the standardized raw data for the components was provided to us in a data cloud for virtual modeling.